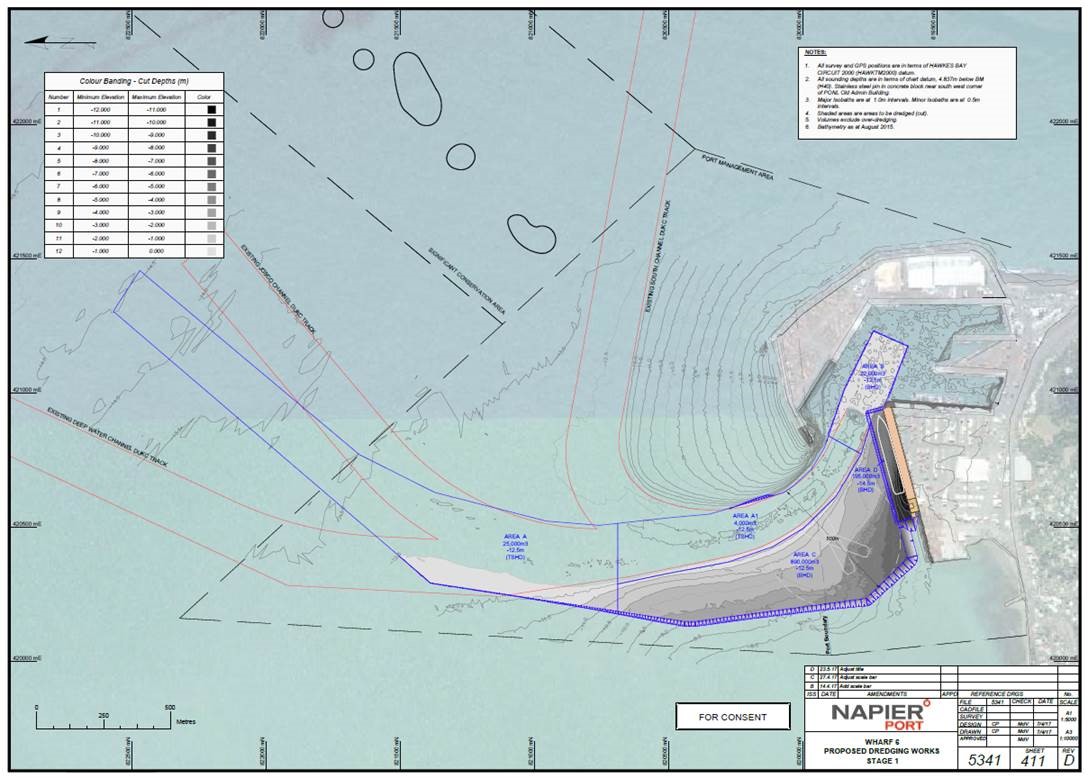

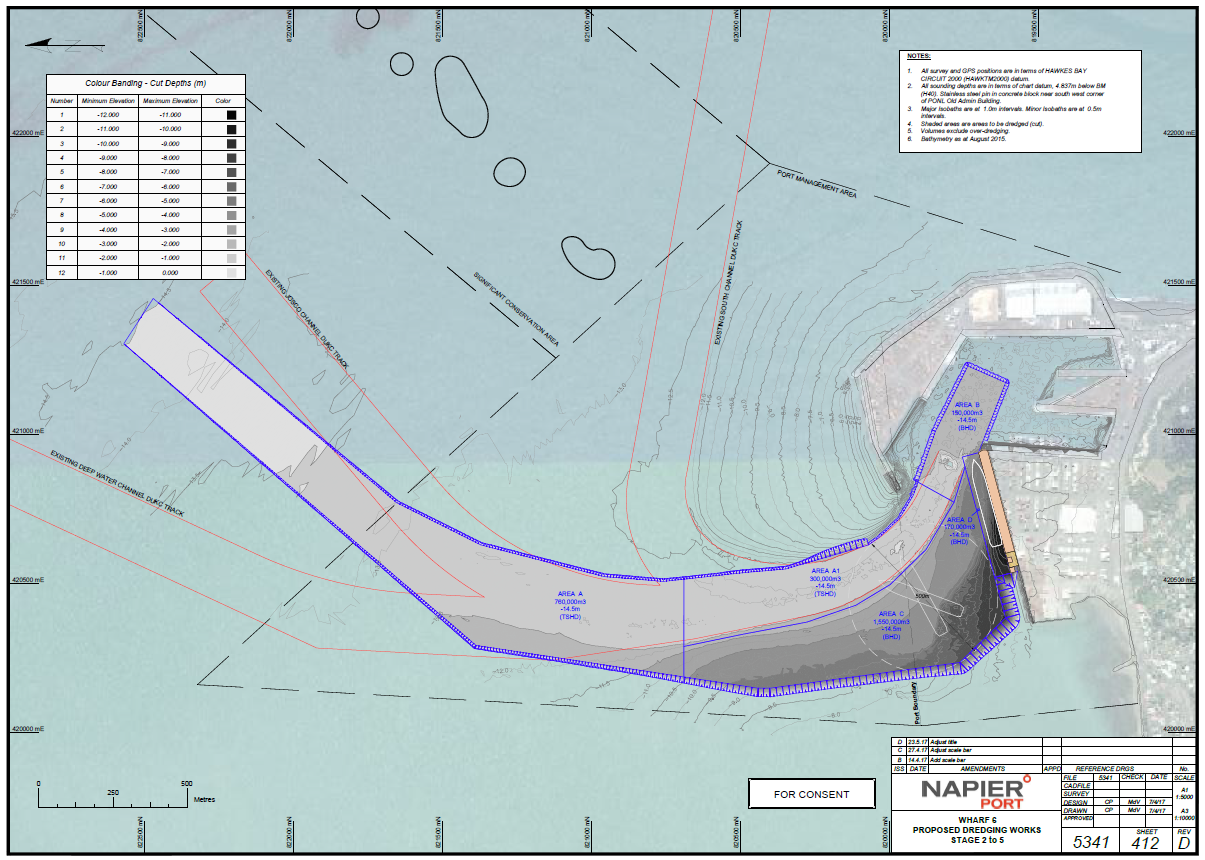

A staged dredging programme

To build 6 Wharf and welcome more and bigger ships, Napier Port needed to create a new vessel turning area and deepen parts of the harbour using a dredge so ships could safely use the wharf.

Dredging is an underwater excavation process that uses a specialised ship to remove sediment in the harbour and deposit it to a disposal area.

For 6 Wharf, we secured resource consents to undertake capital (new) dredging in the wharf area and maintenance dredging.

We also gained resource consent to deposit sediment in a new disposal site 5 kilometres to the east of Napier Port, which will help to protect Pania Reef during dredging and disposal.

Heron Construction and Dredging were the sub-contractor for the stage one dredging work.